RT Couplers

RT Couplers

Ancon RT threaded couplers are among the smallest in the Ancon range, best suited to large scale projects requiring a high volume of couplers. Their small size allows them to be used in places where a larger coupling system may not fit, such as at the end of cogged bars in thin panels.

The Ancon RT threaded coupler range includes Standard, Positional and Weldable couplers. RT threaded couplers require a parallel thread to be rolled onto the end of each reinforcing bar to be coupled prior to placement and fitting of the coupler. Threading of bar for use with RT Threaded Couplers is conducted in our factory. Contact us for further details or to organise bar threading.

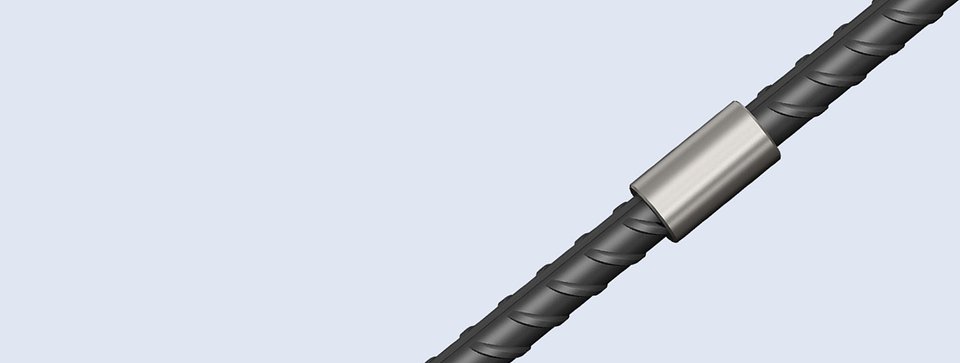

RT Standard Couplers

The Standard RT Threaded Coupler is suitable for connecting two bars of the same diameter, where one bar can be rotated. The ends of the bar are threaded for half the length of the coupler. Contact us regarding situations where rotation of the continuation bar is difficult or impossible.

| Bar Diameter | 12 | 16 | 20 | 25 | 32 | 40 |

|---|---|---|---|---|---|---|

| Product Code | RTC12 | RTC16 | RTC20 | RTC25 | RTC32 | RTC40 |

Contact us for details regarding RTC50 option.

RT Positional Couplers

The RT Positional coupler is designed for use in applications where neither threaded reinforcing bar can be rotated. Due to its degree of adjustability, where a closer between two fixed bars is required the RT Positional coupler is suitable for use. The Ancon RT Positional Coupler utilises the same thread as the standard RT coupler system.

| Bar Diameter | 12 | 16 | 20 | 25 | 32 |

|---|---|---|---|---|---|

| Product Code - Coupler (2x) | RTC12 | RTC16 | RTC20 | RTC25 | RTC32 |

| Product Code - Locknut | RTLN12 | RTLN16 | RTLN20 | RTLN25 | RTLN32 |

| Product Code - Threaded Rod | RTST12 | RTST16 | RTST20 | RTST25 | RTST32 |

Contact us for details regarding 40 and 50mm bar diameter option.

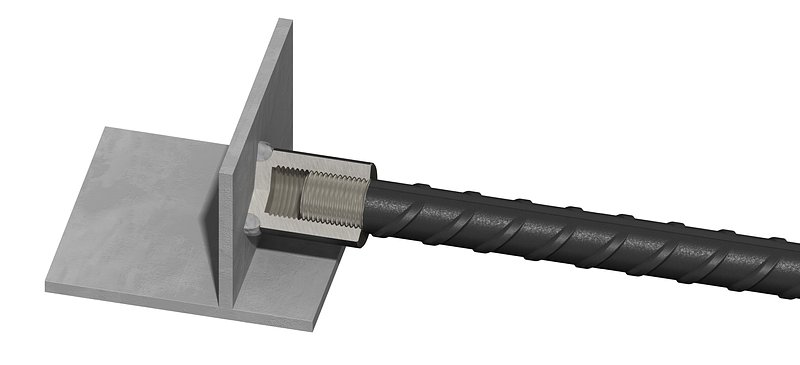

RT Weldable Couplers

The RT Weldable Coupler provides a convenient means of connecting reinforcing bars to structural steel plates or sections. One end has the RT thread form and the other end is prepared for welding to the steel. Ancon RT Weldable Couplers are manufactured from S45C carbon steel according to JIS G 4051: Carbon Steels for Machine Structural Use.

| Bar Diameter | 12 | 16 | 20 | 25 | 32 |

|---|---|---|---|---|---|

| Product Code | RTWC12 | RTWC16 | RTWC20 | RTWC25 | RTWC32 |

Contact us for details regarding RTWC40.

Testing

The Ancon RT system has been tested extensively in New Zealand using local and imported grade E, micro-alloyed reinforcing bar. Testing indicates that the RT system can meet strength, slip and cyclic slip performance criteria stipulated in the Concrete Structures Standard (NZS3101:2006 A3) and the NZTA Bridge Manual. Testing also suggests that variations in steel reinforcement materials, combined with cold-work production processes, may result in reduced ductility and ultimate tensile strength (UTS) in the spliced region relative to the performance of the parent material. Contact us to request a copy of the full New Zealand test details.

Reinforcing Bar Couplers (PDF, 25.9 MB)

Latest News

Holiday Closing 2026

Our offices will close from Thursday, 25th December 2025 and re-open at our usual business hours on Monday, 5th January 2026.

Ancon 500 Tension System renamed to Halfen Detan-D

As a future-oriented, innovative company, Leviat focuses on the ever-changing requirements of the industry, and our latest development combines the portfolio of Ancon and Halfen Tension Systems to ensure we meet the individual requirements of our customers.